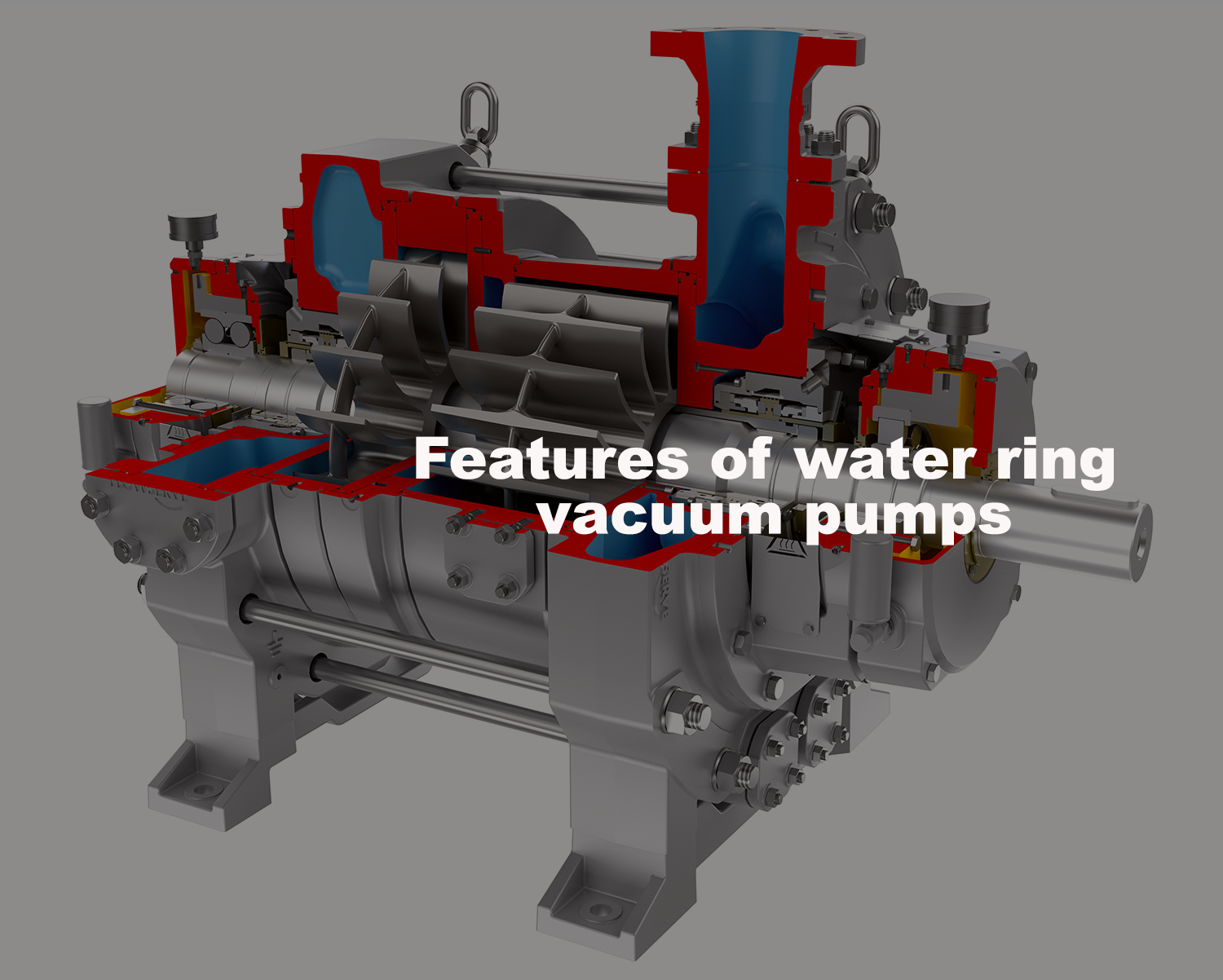

Features of water ring vacuum pumps

Features of water ring vacuum pumps

Liquid ring vacuum pumps are a type of pump that uses a liquid known as a liquid ring to create a vacuum. The pump draws in air or other gases and expels them using the circular motion of the liquid. Some features of liquid ring vacuum pumps include:

High reliability: Liquid ring vacuum pumps operate continuously and reliably. Due to their simple design, malfunctions or malfunctions are rare.

Low noise level: Liquid ring vacuum pumps are known for their quiet operation. The movement of the liquid prevents the propagation of vibrations, ensuring a low noise level.

High suction capacity: Liquid ring vacuum pumps are known for their high suction capacity. Thanks to the vacuum created by the liquid ring, they provide high air flow.

Easy maintenance: Liquid ring vacuum pumps are easy to maintain thanks to their simple design. The main components of the pump are easily accessible and replaceable.

Environmentally friendly: Liquid ring vacuum pumps are an environmentally friendly option. They only need water to work and do not use harmful gases or chemicals.

Cost-effective: Liquid ring vacuum pumps are more cost-effective than other types of vacuum pumps. This is particularly advantageous when large volume pumps are required for industrial applications.

What are water ring vacuum pumps and how do they work?

Water ring vacuum pumps are pumps that create a vacuum using a liquid called a water ring. This pump draws in and expels air or other gases through the movement of the liquid ring. Water ring vacuum pumps are widely used in industrial applications.

A water ring vacuum pump has a cylindrical body that includes a pump cover and rotor. The rotor has an eccentric shape and rotates inside the pump body, causing the liquid ring to move. As the rotor rotates, the water ring creates a portion around the rotor that is used to absorb air or gases.

Air or gases are drawn into the pump through the suction pipe and into the vacuum created by the water ring. This allows the pump to suck in air or gases. Then the drawn gases or air are discharged through the discharge pipe.

A water ring vacuum pump can create varying vacuum levels depending on the water level. The water ring is a ring that rotates around a central force generated by the rotational motion of the pump rotor. This creates a vacuum generating liquid mass that absorbs air or gases.

Water ring vacuum pumps are used in many industrial applications due to their simple design, low noise levels, high suction capacities and environmental friendliness.

Advantages and disadvantages of water ring vacuum pumps

Water ring vacuum pumps have several advantages and disadvantages. Some of the advantages and disadvantages of water ring vacuum pumps are:

Advantages:

High reliability: Water ring vacuum pumps work continuously and reliably. They have a simple design, which means they are less likely to break down or malfunction.

Low noise level: Water ring vacuum pumps are known for their quiet operation. The movement of water ensures a low noise level by preventing the propagation of vibrations. Water ring vacuum pumps are known for their high suction capacity. They provide high air flow thanks to the vacuum created by the water ring.

Easy maintenance: Water ring vacuum pumps have a simple structure, which makes their maintenance easier. The main components of the pump are easily accessible and replaced

Environmentally friendly: Water ring vacuum pumps are an environmentally friendly option. They only need water to work and do not use harmful gases or chemicals.

Cost-effective: Water ring vacuum pumps are more cost-effective than other vacuum pumps. This is particularly advantageous when large volume pumps are required for industrial applications.

Disadvantages:

Water use: Water ring vacuum pumps require water to operate. This can be a disadvantage in areas where water resources are limited.

Low vacuum level: Water ring vacuum pumps may have a lower vacuum level than other vacuum pumps. This may be insufficient for some applications.

Water ring damage: The water ring is important for pump operation. If damaged, the efficiency of the pump may decrease and repair or replacement may be required.

Water level check: Water ring vacuum pumps may not work if they do not have the correct water level. As a result, the water level should be checked regularly.

Water overflow: Water ring vacuum pumps may experience water overflow due to excessive use of water. This may damage the pump and cause environmental pollution.

What should the water ring vacuum pump pay attention to?

There are several important factors to consider when choosing a water ring vacuum pump:

Suction capacity: The suction capacity of the water ring vacuum pump is sufficient for your applications. It will determine whether it is a loop or not. By determining your needs, you should choose a pump that suits your needs.

Vacuum level: Water ring vacuum pumps have a lower vacuum level than other types of vacuum pumps. Therefore, you should check that the pump has the required vacuum level for your application.

Water consumption: Water ring vacuum pumps require water to operate. Therefore, it is important to control the water consumption of the pump. When water resources are limited, it is better to choose a pump with low water consumption.

Pump size: The pump size should be determined according to the size of the area to be applied. Choosing the appropriate pump size can result in higher efficiency and lower energy consumption.

Reliability: The reliability of the pump will affect long-term costs. Choosing a reliable pump can reduce operating costs and avoid interruptions during continuous operation.

Ease of maintenance: Maintenance of the pump is important to increase its life and efficiency. Easy maintenance ensures regular pump maintenance and helps prevent breakdowns.

Cost: The cost of the pump is an important factor in the purchase decision. But not only the cost, but also the performance, durability and reliability of the pump must be considered.

Industrial water ring vacuum pumps manufacturers

Some Turkish manufacturers producing industrial water ring vacuum pumps include:

1.Maki Vacuum Pumps

2.Ozdemir Vacuum Industry

3.Famac Vacuum Pumps

4.Emtivac Vacuum Pumps

5.Provac Vacuum Pumps

6. Vaktim Vacuum Pumps

7.Desal Vacuum Pumps

8. Ideal Vacuum Pumps

9.Vakko Vacuum Pumps

10.Emtaş Vacuum Pumps

These companies manufacture water ring vacuum pumps suitable for a variety of industrial applications with different suction capacities, vacuum levels and water consumption.

household water ring vacuum pump manufacturers

Some Turkish manufacturers producing household water ring vacuum pumps include:

1. Spindle pumps

2.Enes Vacuum Pumps

3.Aksu Vacuum Pumps

4.Vakutek Vacuum Pumps

5.Vakumaxx Vacuum Pumps

6.Vakumix Vacuum Pumps

7.Water Vacuum Pumps

8.Vacuumline Vacuum Pumps

These companies produce water ring vacuum pumps suitable for home use, with a compact design, quiet operation and low power consumption.

Different usage areas of water ring vacuum pumps

Water ring vacuum pumps can be used in many different industries and applications. Some of the application areas are:

Food and Beverage Industry: It is used in vacuum packaging, vacuum filling, vacuum closing and similar processes.

Medical Industry: Used in laboratory and hospital settings for vacuum assisted surgery, blood collection, sterilization and other medical applications.

Chemical Industry: It is used for vacuum drying, vacuum filtration, vacuum distillation and similar processes during chemical processes.

Automotive Industry: It is used in various fields such as fuel system, brake system, air conditioning system.

Packaging Industry: It is used in vacuum packaging processes.

Cleaning Sector: It is used for cleaning by absorbing dirty water.

Other Industrial Applications: Used in a variety of vacuum applications in foundries, paper mills, textile mills and other industries.

Depending on these different application areas, water ring vacuum pumps have different suction capacities, vacuum levels and water consumption levels.

Maintenance and Repair of Water Ring Vacuum Pumps

Maintenance and repair of water ring vacuum pumps is necessary to extend the life of the pump and maintain its high performance. The following steps can be followed for maintenance and repair:

Regular Maintenance: Pump maintenance should be done regularly, including cleaning the water filter, checking the suction valves, checking the hoses and monitoring the water level.

Cleaning the Water Filter: The water filter is very important for the pump to work properly. If the filter is clogged, the suction capacity may decrease or stop altogether. Therefore, the filter should be cleaned regularly.

Checking the Suction Valves: Suction valves are necessary for the pump to prime properly. It should be checked and cleaned if necessary.

Hose Check: The suction hose and discharge hose of the pump should be checked for damage and replaced if necessary.

Water Level Control: The water level of the pump should be constantly monitored. When the water level is low, the pump may be damaged or stop working.

Repair: When the pump fails, it must be repaired by an authorized service technician. Attempting to make repairs without proper knowledge may result in further damage to the pump.

Following these steps can help the water ring vacuum pump run more efficiently and last longer.

Frequently asked questions about water ring vacuum pumps

1. What are water ring vacuum pumps used for?

Water ring vacuum pumps are a type of pump used for the evacuation, transfer or circulation of liquids. to be specificak, water ring vacuum pumps are vacuum pumps that work with the liquid ring principle used in vacuum applications.

2.What are the advantages of water ring vacuum pumps?

The advantages of water ring vacuum pumps are: quiet operation, low maintenance, low vibration, high efficiency, high vacuum level and environmental friendliness.

3.How do water ring vacuum pumps work?

Water ring vacuum pumps work on the liquid ring principle. This principle involves the creation of a liquid ring by the rotation of the pump. The rotor inside the pump rotates within this liquid ring and draws air from the suction valve, creating a vacuum.

4. What are the disadvantages of water ring vacuum pumps?

The disadvantages of water ring vacuum pumps include: high energy consumption, water requirement for the formation of the liquid ring, difficulty in pumping liquids due to the presence of the liquid ring, and unsuitable for use with toxic liquids.

5. In which areas are water ring vacuum pumps used?

Water ring vacuum pumps are used in many areas such as industrial and commercial applications, laboratories, chemical industry, food industry, pharmaceutical industry, paper industry, textile industry, automotive industry, water treatment plants, aviation industry. .

6. How to maintain water ring vacuum pumps?

Maintenance of water ring vacuum pumps should be done regularly. This includes steps such as cleaning the water filter, checking the suction valves, checking the hoses and monitoring the water level.

7. What materials are water ring vacuum pumps made of?

Water ring vacuum pumps are typically made of durable materials such as stainless steel, bronze or nylon.