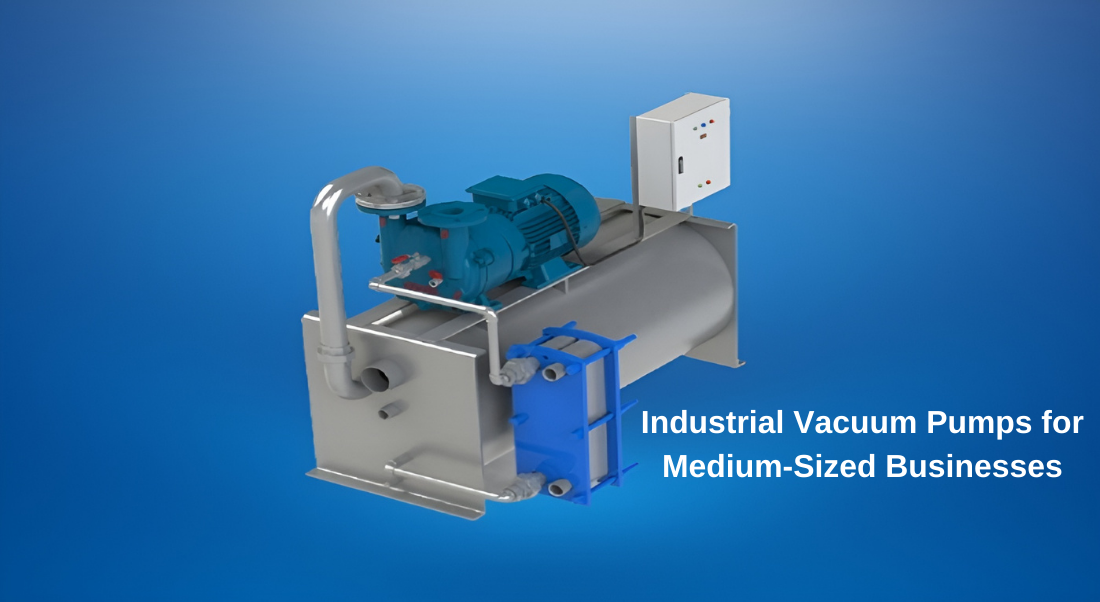

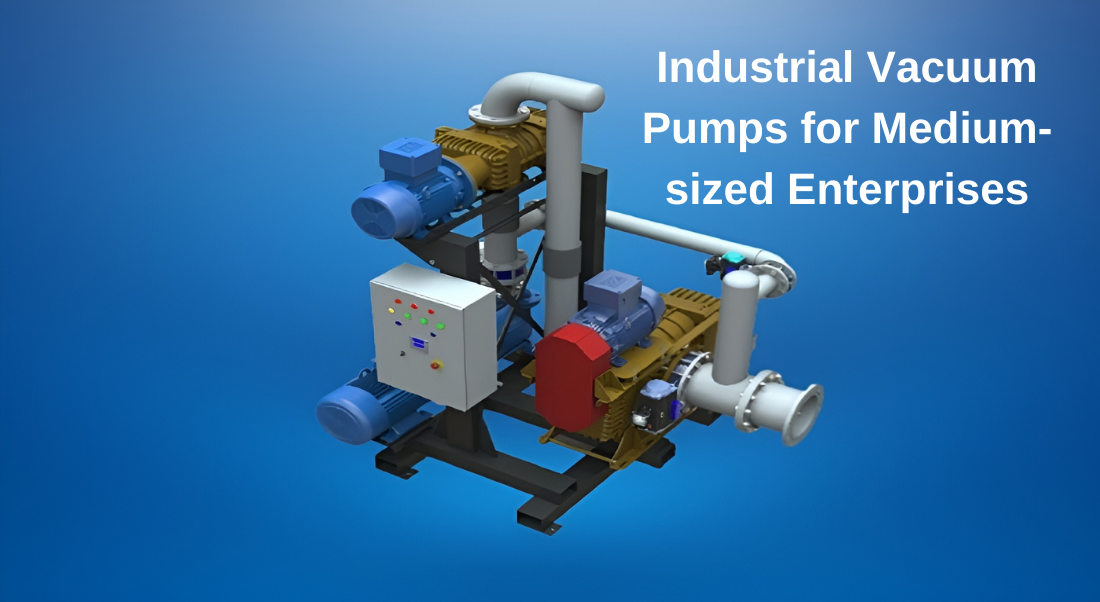

Industrial Vacuum Pumps for Medium-sized Enterprises

The Role of Industrial Vacuum Pumps in Medium-Sized Enterprises

Medium-sized enterprises need industrial vacuum pumps to increase efficiency and expand their production capacities. Vacuum pumps play critical roles in various production processes. Especially in industries such as food processing, pharmaceuticals, chemicals, and automotive, these pumps help speed up processes and improve product quality.

Types of Vacuum Pumps and Their Applications for Medium-Sized Enterprises

Commonly used types of vacuum pumps in medium-sized enterprises include rotary vane pumps, screw pumps, and turbo molecular pumps. Each type has its unique advantages and applications. Rotary vane pumps are common for general purposes, while screw pumps offer higher performance and reliability. Turbo molecular pumps are ideal for precision and high vacuum requirements.

Operating Principle and Basic Components of Vacuum Pumps

The operating principle of vacuum pumps is based on removing air and other gases from systems to create a low-pressure environment. Basic components include compressors, valves, filters, and lubrication systems. These components ensure the efficient and uninterrupted operation of vacuum pumps.

Selection Criteria for Vacuum Pumps for Medium-Sized Enterprises

When selecting a vacuum pump, medium-sized enterprises should consider several important criteria, such as the pump's capacity, energy consumption, maintenance requirements, and total cost of ownership. Choosing a model that meets the specific needs and production processes of the enterprise provides long-term cost savings and operational efficiency.

Energy Efficiency and Contributions of Vacuum Pumps to Enterprises

Energy efficiency is critical for medium-sized enterprises to reduce costs and achieve sustainability goals. Modern vacuum pumps are equipped with energy-saving features. This helps enterprises reduce their energy costs and minimize their environmental impact

.

Maintenance and Repair Strategies for Vacuum Pumps

Regular maintenance and repair of vacuum pumps are essential to maintain their performance. Medium-sized enterprises should plan maintenance processes and seek expert support when necessary. Regular maintenance extends the life of pumps, prevents unexpected breakdowns, and ensures operational continuity.

Benefits of Vacuum Pumps for Medium-Sized Enterprises

Vacuum pumps offer various benefits to medium-sized enterprises. These include speeding up production processes, improving product quality, and reducing operating costs. Additionally, the use of vacuum pumps contributes to reducing environmental impacts, helping enterprises achieve their sustainability goals.

Industrial Applications of Vacuum Pumps

Industrial vacuum pumps have a wide range of applications in various sectors such as food processing, pharmaceuticals, chemicals, electronics, and automotive. Due to the different needs of each sector, selecting and using the right vacuum pump is crucial. For example, pumps that meet hygiene standards should be used in the food processing industry, while chemical-resistant pumps should be preferred in the chemical industry.

Environmental Impact and Sustainability of Vacuum Pumps

The environmental impact of vacuum pumps should be evaluated in terms of energy consumption and waste gas emissions. Energy-efficient models and regular maintenance are critical to minimizing environmental impacts. This helps enterprises develop eco-friendly policies and achieve their sustainability goals.

Technological Developments and the Future of Vacuum Pumps

Vacuum pumps are continuously being updated with technological developments. Innovative designs and advanced features enable medium-sized enterprises to work more efficiently and effectively. For example, smart control systems and IoT (Internet of Things) integrations allow vacuum pumps to be monitored and controlled remotely.

Cost Analysis and Return on Investment of Vacuum Pumps

The cost analysis of vacuum pumps includes factors such as initial investment cost, energy consumption, and maintenance and repair expenses. Medium-sized enterprises should conduct these analyses to determine the most cost-effective solution. Proper analysis helps enterprises use their budgets more effectively and maximize return on investment.

Installation and Integration Processes of Vacuum Pumps

The correct installation and integration of vacuum pumps into existing systems are crucial for efficient operation. Attention to installation details and integration processes ensures smooth operation for enterprises. Professional installation services enhance the performance and reliability of the pumps.

Safety and Worker Health Measures with Vacuum Pumps

When using vacuum pumps, safety measures must be taken. Proper usage guidelines should be followed, and personnel should be trained. This is important for preventing potential accidents and creating a safe working environment. Worker health and safety are the responsibility of enterprises, and they should provide the necessary training and equipment for the safe use of vacuum pumps.

Recommendations for Vacuum Pumps for Medium-Sized Enterprises

Recommendations on the most suitable vacuum pump models and brands for medium-sized enterprises help them make the right choice. User experiences and expert opinions can provide guidance on this matter. Enterprises can increase their efficiency and profitability by selecting the model that best suits their needs.

Cooling Systems and Energy Savings in Vacuum Pumps

Modern vacuum pumps are equipped with advanced cooling systems. These systems prevent the pumps from overheating and enhance energy efficiency. Medium-sized enterprises can reduce costs and increase operational efficiency thanks to these energy-saving technologies.

Performance Evaluation and Optimization of Vacuum Pumps

Evaluating the performance of vacuum pumps is important for enterprises to achieve their efficiency goals. Performance evaluation covers factors such as pump capacity, energy consumption, and operating time. This evaluation is necessary to measure the effectiveness of pumps and identify areas for improvement. Optimization efforts ensure that pumps operate at maximum efficiency.

Automation and Digitalization Processes of Vacuum Pumps

Automation and digitalization make the use of vacuum pumps more efficient and user-friendly. Medium-sized enterprises can remotely monitor and control vacuum pumps through automation systems. This increases operational efficiency and minimizes human errors. Digitalization makes it possible to predict maintenance needs in advance and ensure uninterrupted operation.

Economic Advantages Provided by Vacuum Pumps

Vacuum pumps offer various economic advantages to medium-sized enterprises. Due to energy efficiency and low maintenance costs, operational expenses of enterprises decrease. Additionally, speeding up production processes and improving product quality increase the competitiveness of enterprises. These economic advantages contribute to the growth and sustainability of enterprises.

Training and Safety Protocols for Vacuum Pumps

When using vacuum pumps, training employees and adhering to safety protocols are vital. Training employees on the proper use and maintenance processes of pumps enhances job safety. Additionally, knowing and implementing emergency procedures is important. Enterprises provide a safe and efficient working environment through these protocols.

Post-Installation Support Services for Vacuum Pumps

Post-installation support services for vacuum pumps are a critical factor for medium-sized enterprises. Support services provided by manufacturers ensure the efficient and trouble-free operation of the pump. Technical support, spare parts supply, and maintenance services support the operational continuity of enterprises. These services enhance the performance and longevity of the pumps.

Conclusion

For medium-sized enterprises, industrial vacuum pumps are indispensable for optimizing production processes, increasing energy efficiency, and reducing costs. The correct selection of pumps, regular maintenance, and vacuum pumps equipped with innovative technologies will increase the efficiency and competitiveness of enterprises. This guide helps enterprises become knowledgeable about vacuum pumps and find the most suitable solution.