Laboratory Vacuum Pump Manufacturer

Contents

- What Type of Laboratory Vacuum Pumps Do You Produce?

- Can Your Laboratory Vacuum Pumps Adapt to Various Laboratory Applications?

- Are Your Laboratory Vacuum Pumps Suitable for Use with Sensitive Laboratory Equipment?

- Do You Offer Customization Options to Meet Special Research Needs of Laboratory Vacuum Pumps?

- What is the Typical Lifespan of Your Laboratory Vacuum Pumps in Regular Laboratory Use?

What Type of Laboratory Vacuum Pumps Do You Produce?

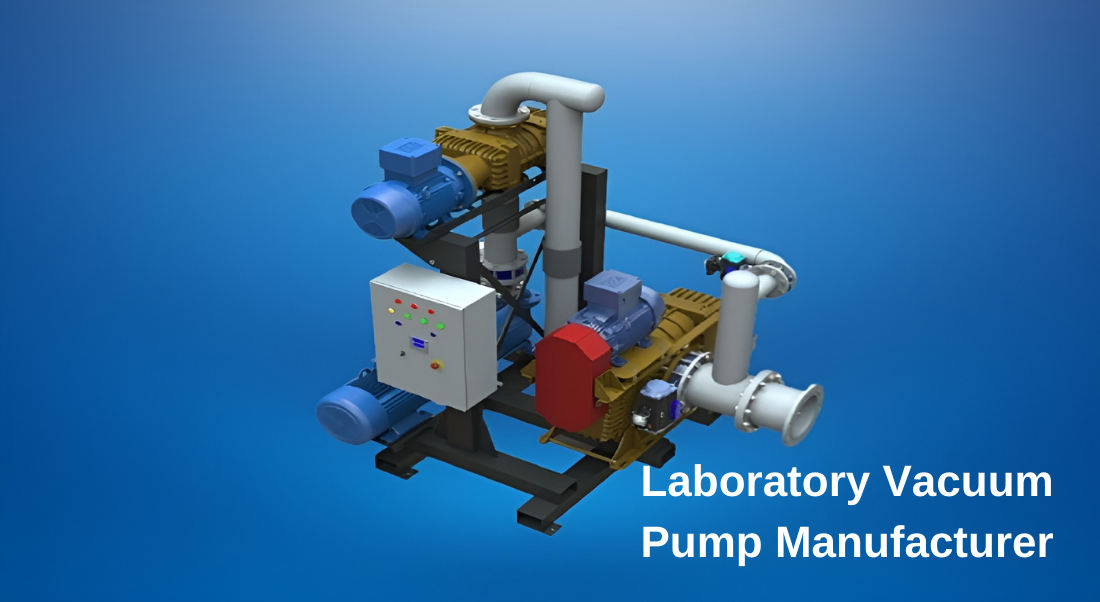

As a leading laboratory vacuum pump manufacturer, we offer a wide range of vacuum pump solutions designed to meet the specific needs of laboratory applications. Our product range covers several types of vacuum pumps, each designed to provide optimum performance and reliability in laboratory environments.

One of the primary types of laboratory vacuum pumps we manufacture is the rotary vane pump. Rotary vane pumps are widely used in laboratories due to their ruggedness, versatility, and ability to produce vacuum efficiently. They work by using rotating vanes to create a vacuum within the pump chamber, making them suitable for a wide range of laboratory tasks including filtration, degassing and vacuum drying.

We also specialize in the production of diaphragm vacuum pumps that offer various advantages for laboratory applications. Diaphragm pumps use a flexible diaphragm to create vacuum pressure, eliminating the need for lubrication and minimizing the risk of sample contamination. These pumps are particularly suitable for applications that require a clean, oil-free vacuum environment, such as sensitive analytical instruments such as mass spectrometers and electron microscopes.

Our product range also includes dry scroll vacuum pumps, known for their reliability, low maintenance requirements and oil-free operation. Dry scroll pumps use interlocking scrolls to compress and pump gas; This makes them ideal for applications where oil contamination must be prevented, such as semiconductor manufacturing and research laboratories.

In addition to these primary types, we also manufacture other specialized vacuum pumps suitable for specific laboratory applications, including diffusion pumps, turbomolecular pumps and cryogenic pumps. These pumps are designed to meet the unique requirements of advanced research and analytical processes, providing high levels of vacuum performance and stability.

Overall, our laboratory vacuum pump offerings cover a wide range of pump types to meet different laboratory requirements, ensuring researchers and scientists have access to reliable and efficient vacuum solutions for their experiments and analyses.

Can Your Laboratory Vacuum Pumps Adapt to Various Laboratory Applications?

Our laboratory vacuum pumps are specifically designed to suit a wide range of laboratory applications, offering versatility, reliability and performance across a variety of scientific disciplines. Whether in academic research, industrial R&D or quality control laboratories, our vacuum pumps are designed to meet the diverse needs of laboratory professionals.

Our pumps are highly adaptable and can be used in a multitude of laboratory applications including:

Filtration: Laboratory vacuum pumps are commonly used in filtration processes such as vacuum filtration and Büchner funnel filtration to efficiently separate solids from liquids.

Evaporation and Concentration: In applications requiring solvent evaporation or concentration, vacuum pumps enable concentration of samples or removal of solvents by creating a low-pressure environment to facilitate faster evaporation rates.

Degassing: Vacuum pumps are essential for degassing processes where trapped gases are removed from liquids or solids to improve the purity and integrity of the sample.

Distillation: Vacuum distillation processes, such as short-path distillation and rotary evaporation, rely on vacuum pumps to lower the boiling points of substances, allowing volatile compounds to be separated at lower temperatures.

Analytical Instruments: Laboratory vacuum pumps play a key role in supporting analytical instruments, including mass spectrometers, electron microscopes and gas chromatographs, ensuring optimum performance and sample integrity by creating vacuum environments free of contaminants.

Sample Preparation: Vacuum pumps facilitate a variety of sample preparation techniques essential for downstream analyzes in molecular biology, biochemistry and materials science laboratories, from freeze-drying to solvent extraction.

Environmental Testing: Environmental laboratories use vacuum pumps to sample air, vacuum ovens to test material properties under vacuum conditions, and other specialized applications.

Vacuum Drying: Vacuum pumps assist in the drying process in which moisture is removed from samples or materials, preserving their stability and integrity.

By offering a wide range of laboratory vacuum pumps, including rotary vane, diaphragm, dry scroll and specialty pumps, we ensure that researchers and scientists have access to reliable and efficient vacuum solutions tailored to their specific applications. Our pumps are designed to be precise and durable, delivering consistent performance in a variety of laboratory environments and contributing to the success and advancement of scientific endeavors.

Are Your Laboratory Vacuum Pumps Suitable for Use with Sensitive Laboratory Equipment?

Our laboratory vacuum pumps are specifically designed to be suitable for use with sensitive laboratory equipment; provides optimum performance, precision and reliability while maintaining the integrity of precision instruments and samples.

Laboratory equipment such as mass spectrometers, electron microscopes, and analytical instruments often require a stable and contaminant-free vacuum environment to operate effectively and provide accurate results. Our vacuum pumps are designed with advanced features and technologies to meet these stringent requirements:

Low Noise and Vibration: Our vacuum pumps are designed to operate quietly and with minimal vibration, reducing disturbances to sensitive equipment and minimizing the risk of measurement error or device damage.

Oil-Free Operation: Many of our laboratory vacuum pumps use oil-free or oil-free technologies, eliminating the risk of oil contamination in the vacuum system. This ensures the purity of the vacuum environment, which is crucial for sensitive analytical techniques and prevents interference with sample analyses.

Chemical Resistance: Our pumps are manufactured from materials that are resistant to corrosive chemicals and harsh solvents commonly used in laboratory applications. This ensures long-term reliability and prevents damage to the pump or contamination of the vacuum environment.

Stable Vacuum Control: Our vacuum pumps are equipped with precision vacuum control mechanisms that allow users to maintain constant vacuum levels necessary for the correct operation of precision instruments and processes.

Integrated Safety Features: We incorporate safety features such as thermal protection, overpressure protection, and automatic shutdown systems to protect both the vacuum pump and connected equipment from damage or malfunction.

Compact and Space-Saving Design: Most of our laboratory vacuum pumps have a compact footprint, making them ideal for integration into crowded laboratory spaces while providing efficient vacuum performance.

Comprehensive Support: We provide comprehensive technical support, including installation guidance, troubleshooting assistance, and maintenance services, ensuring laboratory professionals can effectively integrate and use our vacuum pumps with their precision equipment.

By providing laboratory vacuum pumps tailored to the needs of precision laboratory equipment, we enable researchers, scientists and technicians to conduct their experiments and analyzes with confidence knowing that their vacuum systems are optimized for accuracy, reliability and performance.

Do You Offer Customization Options to Meet Special Research Needs of Laboratory Vacuum Pumps?

We offer customization options for laboratory vacuum pumps to meet specific research needs and meet a variety of applications and requirements. Our commitment to providing custom solutions stems from the understanding that different research efforts may require unique vacuum system configurations, performance characteristics, and compatibility with specialized equipment.

Our customization capabilities include:

Variable Pump Configurations: We configure laboratory vacuum pumps with a variety of pump types, including diaphragm pumps, rotary vane pumps, and scroll pumps, allowing researchers to select the most appropriate pump technology for their specific application.

Vacuum Level Adjustments: Depending on research needs, we can adjust the vacuum level capabilities of pumps to meet specific pressure ranges required for different experimental setups or analytical techniques.

Chemical Compatibility: We can select materials and coatings for pump components to ensure compatibility with certain chemicals or solvents commonly encountered in the research environment and to prevent corrosion and contamination.

Custom Fittings and Connections: Our customization services extend to providing custom fittings, adapters and ports to facilitate seamless integration with existing laboratory equipment or experimental setups.

Size and Footprint: We can vary the size and footprint of vacuum pumps to accommodate space constraints in the laboratory environment, ensuring optimal placement and efficient use of available workspace.

Control and Monitoring Features: We can integrate special control and monitoring features into vacuum pumps, such as remote operation capabilities, digital interfaces, and data logging functions, to increase usability and facilitate integration with laboratory automation systems.

Noise Reduction and Vibration Damping: In noise-sensitive research environments, we can incorporate noise reduction technologies and vibration dampening mechanisms into the pump design to minimize disturbances and provide a quiet work area.

Standards Compliance: Our customized vacuum pumps can be designed to meet specific industry standards, safety regulations, and compliance requirements relevant to the research area or application area.

By offering exclusive customization options, we empower researchers and laboratory professionals to optimize vacuum systems to the unique demands of their research projects, providing enhanced performance, reliability and efficiency in their scientific work.

What is the Typical Lifespan of Your Laboratory Vacuum Pumps in Regular Laboratory Use?

The typical lifespan of our laboratory vacuum pumps in regular laboratory use may vary depending on a variety of factors, including frequency of use, maintenance practices, operating conditions and the specific model of the vacuum pump. But on average, our laboratory vacuum pumps are designed and manufactured to provide reliable performance and long life for many years of continuous operation.

Under normal laboratory use, where pumps are operated within specified performance parameters and subject to routine maintenance as recommended by the manufacturer, our vacuum pumps can typically last 5 to 10 years or more. This lifespan estimate is based on empirical data collected from real-world usage scenarios and is subject to variability depending on individual usage patterns and environmental factors.

To maximize the life of our laboratory vacuum pumps, we recommend following the following best practices:

Regular Maintenance: Performing routine maintenance tasks such as cleaning, lubrication, and inspection according to the manufacturer's instructions can help prevent premature wear and extend the life of pump components.

Optimum Operating Conditions: Operating vacuum pumps under specified temperature, pressure and environmental conditions can prevent excessive stress on pump components and ensure optimum performance and long life.

Avoiding Overloading: Avoiding overloading vacuum pumps beyond their rated capacity and ensuring proper sizing for the intended application can prevent undue stress on the pump motor and components and extend their life.

Quality of Components: Our laboratory vacuum pumps are manufactured using high quality materials and components selected for their durability and reliability, contributing to longer operating life in regular laboratory use.

Quick Repair: Promptly addressing any signs of abnormal noise, vibration, or performance degradation through timely repair and service can prevent minor problems from developing into more significant problems that can affect the life of the pump.

Although these guidelines help optimize the life of our laboratory vacuum pumps, it is important to be aware that individual usage habits and environmental factors can affect actual life. Therefore, we encourage you to consult our technical support team for personalized recommendations and assistance in maximizing the life of your laboratory vacuum pump investment.