Use of Industrial Vacuum Pumps in Laboratories

Contents

- What are Industrial Vacuum Pumps? What is the Basic Working Principle?

- How to Use Vacuum Pumps in Laboratories?

- What are the General Advantages of Vacuum Pumps and How to Benefit?

- In Which Situations Are Industrial Vacuum Pumps Needed?

- What are the Basic Terms and Meanings Related to Vacuum Pumps?

- In Which Industrial Processes Are Vacuum Pumps Used? Practical Examples

- What is the Role of Laboratory Safety and Industrial Vacuum Pumps?

- What is the Maintenance of Vacuum Pumps?

What are Industrial Vacuum Pumps? What is the Basic Working Principle?

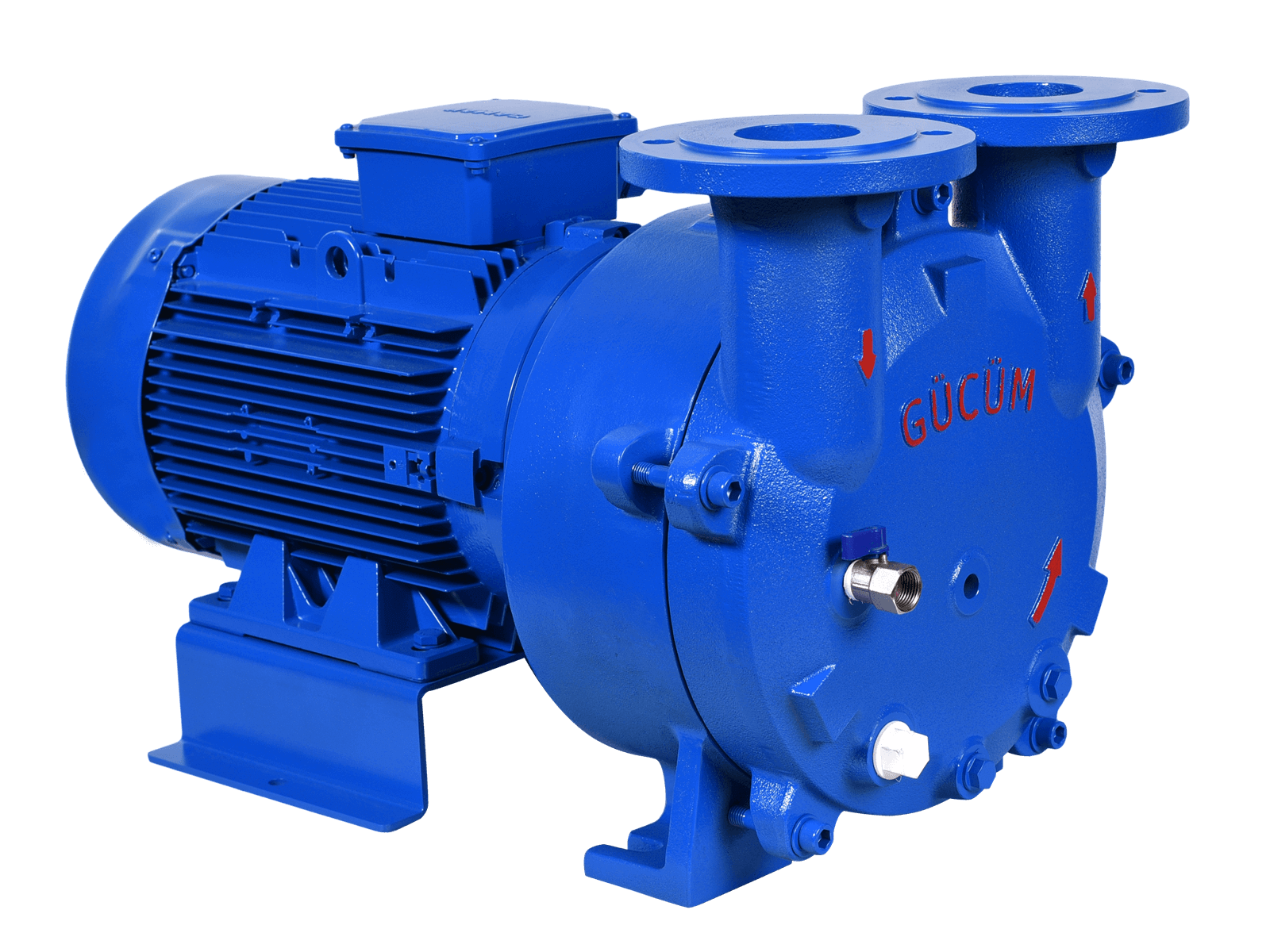

Industrial vacuum pumps are essential equipment used in various industrial processes. Essentially, these pumps create a vacuum by drawing air or gas from the environment. These machines play a crucial role in many sectors, such as material handling, packaging, chemical processes, and vacuum drying.

The basic operating principle of industrial vacuum pumps is quite simple. They create a vacuum by reducing the pressure inside a closed system. This vacuum is utilized in various industrial facilities and laboratories for different processes. The efficiency provided by industrial vacuum pumps in applications such as material transfer, vacuum drying, and packaging helps optimize production processes.

Proper use of these powerful devices is critical to increasing the efficiency of industrial facilities and improving production quality. Industrial vacuum pumps come in different types to meet the needs of businesses in various industries, each designed with specific applications in mind.

If you aim to enhance efficiency in industrial processes and optimize your operations, it might be the right time to evaluate the advantages offered by industrial vacuum pumps. These robust devices play an indispensable role in modern industrial applications and can be a significant investment for your business.

How to Use Vacuum Pumps in Laboratories?

Effective use of vacuum pumps in laboratories is crucial for the successful execution of scientific experiments and laboratory work. These pumps perform pressure reduction by pulling air from an environment, thereby assisting in creating specific conditions in the laboratory.

The first step in using vacuum pumps correctly is to select the pump type based on its purpose and usage. Subsequently, proper assembly and positioning of the pump are essential. Correct adjustment of the pump's connection points and conducting leak checks is important for achieving the desired vacuum level.

Laboratory experts should regularly monitor and adjust vacuum levels during experiments. Additionally, regular maintenance of vacuum pumps is crucial to extend their lifespan and enhance efficiency.

Implementing these processes correctly contributes to reliable results in laboratory work. The use of vacuum pumps in laboratories increases the accuracy of experiments and provides researchers with control and flexibility for various applications.

What are the General Advantages of Vacuum Pumps and How to Benefit?

Vacuum pumps, widely used in various industrial applications, offer several advantages. Firstly, these pumps can create a vacuum by evacuating air from the environment, playing a significant role in many industrial processes. The advantages include:

Working with Vacuum

Vacuum pumps are used in various industrial processes by creating a vacuum, providing advantages in industries ranging from packaging to electronic manufacturing.

Material Handling and Processing

Vacuum pumps are utilized in material transfer systems, ensuring precise and controlled material transfer for increased production efficiency.

Vacuum Drying

Vacuum pumps contribute to industrial drying processes by ensuring quick and effective drying of materials.

Chemical and Physical Processes

Vacuum is a fundamental factor in many chemical and physical processes, and vacuum pumps assist in establishing vacuum conditions.

Air Pollution Control

Vacuum pumps can be used in industrial facilities to control air pollution, reducing the environmental impact of various industrial activities.

Sharing this information on your website not only informs your visitors about the general advantages of vacuum pumps but also illustrates how they can be utilized in industrial applications. This can enhance your content by providing valuable insights into the practical use of vacuum pumps.

In Which Situations Are Industrial Vacuum Pumps Needed?

Industrial vacuum pumps play a significant role in various applications and industrial processes. The need for these pumps arises in different situations and industries. Here are some examples of situations where industrial vacuum pumps are required:

Packaging Industry

In the packaging industry, vacuum pumps prevent the intake of air while vacuum sealing, preserving the freshness of products. Vacuum pumps are commonly used in precision packaging applications, especially in the food industry.

Manufacturing and Production

Many manufacturing processes, including material transfer, drying, and material processing, require the use of vacuum. Vacuum pumps are employed in industrial production facilities to enhance efficiency.

Electronic Industry

The production of electronic components often requires precise vacuum levels. Vacuum pumps are essential equipment in this industry to ensure the desired vacuum conditions.

Chemical Industry:

Various chemical processes necessitate the creation of a vacuum. Vacuum pumps are employed in processes such as distillation, drying, and filtration in the chemical industry.

Medical and Health:

In the medical field, vacuum pumps are used in laboratory applications, surgical processes, and other medical devices.

These examples highlight the versatile use of industrial vacuum pumps. By sharing this information on your website, you can educate your visitors about the extensive application of vacuum pumps across different industries, emphasizing their vital role.

What are the Basic Terms and Meanings Related to Vacuum Pumps?Understanding key terms related to vacuum pumps is essential for their effective and safe use. Here are some fundamental terms associated with vacuum pumps:

Vacuum Levels

Vacuum pumps perform evacuation processes up to a specific pressure level. These levels are usually expressed in units such as "torr" or "pascal" and indicate the strength of the vacuum.

Types of Vacuum Pumps

Vacuum pumps come in various types designed for different applications. Examples include rotary piston pumps, diffusion pumps, and membrane pumps, each tailored to specific needs.

Vacuum ConveyingVacuum pumps transport gases or liquids from one place to another by creating a vacuum. This process is crucial in material transfer and processing operations.

Vacuum Gauges

Devices used to measure vacuum levels. There are two types: capacitance manometers and diaphragm manometers. These devices are essential for continuously monitoring vacuum levels.

Understanding these key terms enhances awareness of the functionality, maintenance, and safe use of vacuum pumps. Focusing on these terms on your website can provide valuable information to visitors, increasing their knowledge of the complex world of vacuum pumps.

In Which Industrial Processes Are Vacuum Pumps Used? Practical Example

Vacuum pumps find effective use in a wide range of industrial processes. Their versatility allows for increased efficiency and tailored solutions in various sectors. Specifically:

Food Industry

Vacuum pumps contribute to packaging processes by extending the shelf life of products through vacuum sealing. They are crucial in preserving the freshness of food items.

Electronic Manufacturing

In electronic component production, vacuum pumps help minimize the interaction of air and moisture with electronic components, thereby improving product quality.

Chemical Industry

Various chemical processes, including distillation and drying, rely on vacuum pumps to create the necessary vacuum conditions for optimal performance.

Medical and Laboratory Applications

Vacuum pumps are integral in laboratory setups and medical devices. They contribute to processes such as filtration, sample preparation, and creating controlled environments.

By sharing this information on your website, you can inform your visitors about the wide application of vacuum pumps. Illustrating practical examples enhances their understanding of how vacuum pumps can benefit different industries.

What is the Role of Laboratory Safety and Industrial Vacuum Pumps?

Laboratory safety is a fundamental aspect of research and development activities, with the safe and effective operation of equipment playing a crucial role. Industrial vacuum pumps contribute significantly to laboratory safety.

These pumps are employed in laboratories for tasks such as the absorption of chemical substances, filtration, drying, and distillation. This ensures the controlled removal of hazardous gases and vapors from the environment. Vacuum pumps also play a role in maintaining vacuum levels in vacuum-operated devices and systems.

From a laboratory safety perspective, vacuum pumps minimize the evaporation of chemical substances, thereby enhancing personnel health and environmental safety. Additionally, these pumps are critical for maintaining and stabilizing vacuum systems in laboratory equipment.

By sharing this information on your website, you can emphasize how laboratory safety can be optimized through the use of industrial vacuum pumps. This underscores your expertise in providing reliable and effective laboratory solutions

What is the Maintenance of Vacuum Pumps?

Regular maintenance and effective troubleshooting are crucial for ensuring the longevity and efficient operation of vacuum pumps. Here are some tips and key points for maintenance and troubleshooting:

Filter Cleaning

Filters of vacuum pumps should be cleaned regularly. Dirty filters can reduce performance and potentially harm the pump.

Checking Oil Levels

In oil-sealed vacuum pumps, oil levels should be periodically checked. Maintaining the correct oil level ensures the pump operates effectively.

Inspection of Seals

Regularly inspecting the seals of the vacuum pump is essential to prevent leaks. Worn or damaged seals should be replaced promptly.

Cooling System Maintenance

Vacuum pumps with cooling systems require regular maintenance to prevent overheating. Checking cooling fluid levels and circulation is necessary.

Vacuum Level Testing

Regularly testing the vacuum level of the pump helps determine its performance. This can aid in detecting potential issues in advance.

In case of troubleshooting, users can refer to the pump's manual or seek expert technical support. By sharing these maintenance tips and troubleshooting key points on your website, you can provide valuable information to visitors, helping them use vacuum pumps reliably and effectively.