Use of Vacuum Pumps in the Chemical Industry

Use of Vacuum Pumps in the Chemical Industry: Tips for Efficient Production

The chemical industry requires complex and precise processes for the production, processing, and storage of various chemicals. The technologies used are crucial for ensuring that production processes are efficient, safe, and cost-effective. Vacuum pumps are an indispensable tool in the chemical industry to achieve these goals. In this article, we will explore how vacuum pumps are used in the chemical industry and their importance in enhancing efficiency in production processes.

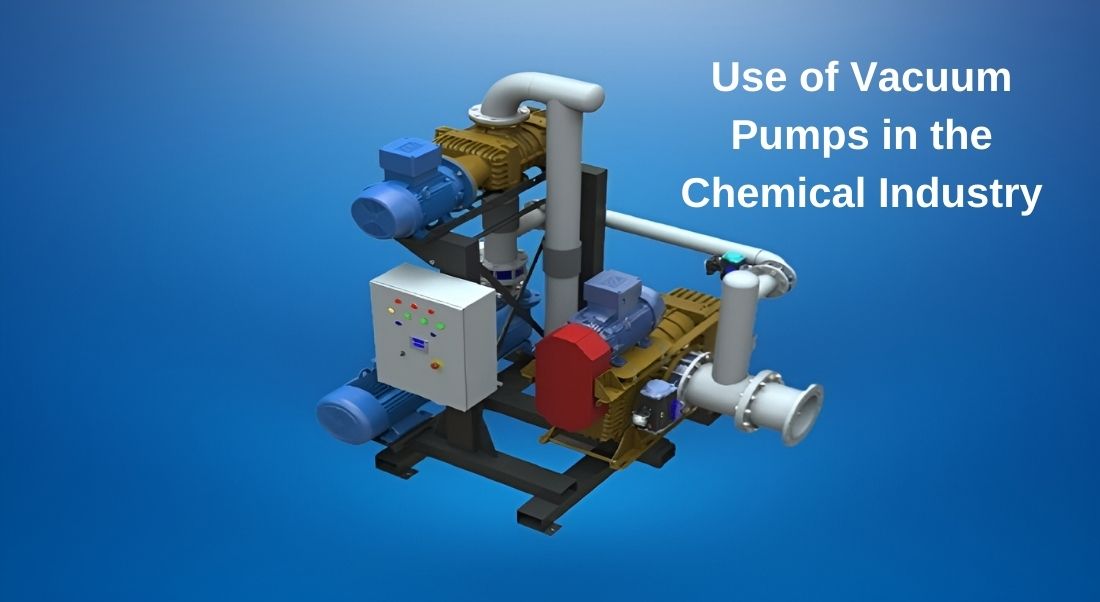

What is a Vacuum Pump and How Does it Work in the Chemical Industry?

A vacuum pump is a device that creates a low-pressure environment (vacuum) by drawing air or gas out of a space. In the chemical industry, vacuum pumps are used in various processes to accelerate and enhance the efficiency of transporting, separating, and distilling gases, liquids, or solids. Vacuum is essential in many chemical processes because many reactions occur more efficiently under low-pressure conditions.

Working Principle of a Vacuum Pump

Vacuum pumps typically consist of piston or rotary blade systems driven by a motor. These systems compress incoming air and gases, expelling them and thereby creating a vacuum. The characteristics of vacuum pumps used in the chemical industry vary depending on the type of process and materials involved. Often, rotary, oil-lubricated, or oil-free vacuum pumps are preferred to achieve low or medium vacuum levels.

Applications of Vacuum Pumps in the Chemical Industry

Vacuum pumps are used in various stages of production and processing in the chemical industry. Let's look at these applications in more detail:

Chemical Distillation and Separation

Vacuum is commonly used in distillation processes in the chemical industry. Distillation is a process that separates the components of a liquid based on differences in their boiling points. However, when certain chemicals have very high boiling points, using a vacuum can lower these boiling points, making the process more efficient. For example, in solvent distillation, a low-pressure environment enables faster and more energy-efficient separation of components.

Vacuum Drying

Vacuum drying is a process where moisture is removed from chemicals or products under low pressure, often with the aid of heat. This method is particularly useful for drying heat-sensitive materials. Vacuum drying allows rapid drying without exposing the substance to high temperatures, minimizing quality loss. This technique is widely used in the pharmaceutical and biotechnology industries as well.

Accelerating Reactions

Many chemical reactions occur faster and more efficiently under vacuum. Using vacuum to increase reaction speed under low-pressure conditions shortens production times and enhances efficiency. Additionally, vacuum environments can help prevent side reactions and reduce the formation of unwanted compounds.

Gas and Vapor Removal

In chemical production, certain processes may require the absorption of gases and vapors. Vacuum pumps are used to remove these gases, keeping the environment clean and preventing the accumulation of unwanted vapors. This is particularly important during chemical reactions where harmful gases may accumulate, posing safety risks.

Vacuum Pump Selection and Efficiency in the Chemical Industry

Choosing the right vacuum pump is crucial for achieving production efficiency in the chemical sector. Not every vacuum pump is suitable for every process or application. Here are some factors to consider when selecting the right vacuum pump:

Required Vacuum Level

Chemical processes require different vacuum levels. Therefore, the vacuum pump used must have the capacity to achieve the desired vacuum level. For processes requiring high vacuum levels, more powerful pumps are chosen, while lower vacuum levels may be handled by smaller, energy-efficient pumps.

Pump Type and Material Compatibility

Material compatibility is also important when selecting vacuum pumps in the chemical industry. The materials used in the pump should be compatible with the internal components to prevent failures due to chemical reactions or corrosion. Pumps working with aggressive chemicals or high temperatures should be made from durable materials such as stainless steel or titanium.

Energy Efficiency and Maintenance

Energy efficiency is a key factor in reducing production costs. Vacuum pumps with low energy consumption can provide significant savings over the long term. Additionally, regular maintenance ensures that pumps operate efficiently and minimizes the risk of breakdowns. Oil-free pumps can be a good choice to minimize maintenance costs, as they require less upkeep.

Advantages of Using Vacuum Pumps

When used correctly, vacuum pumps provide numerous benefits in the chemical industry:

Increased Production Speed

Vacuum systems can accelerate chemical processes. Processes conducted under low pressure are completed faster, increasing production speed. Additionally, vacuum environments often result in more uniform outcomes, improving product quality.

Energy Savings

Vacuum processes typically require less energy. For instance, distillation under vacuum can be done at lower temperatures, reducing energy consumption. Energy efficiency reduces costs and promotes an environmentally friendly production process in the chemical industry.

Improved Product Quality

Vacuum processes improve product quality, especially when dealing with heat-sensitive compounds. High temperatures can cause degradation of certain compounds, but using vacuum minimizes this risk. Vacuum also helps prevent undesirable side reactions.

Safety

Vacuum systems ensure that explosive gases or vapors that may arise during chemical reactions are absorbed. This enhances safety during production and protects the health of workers.