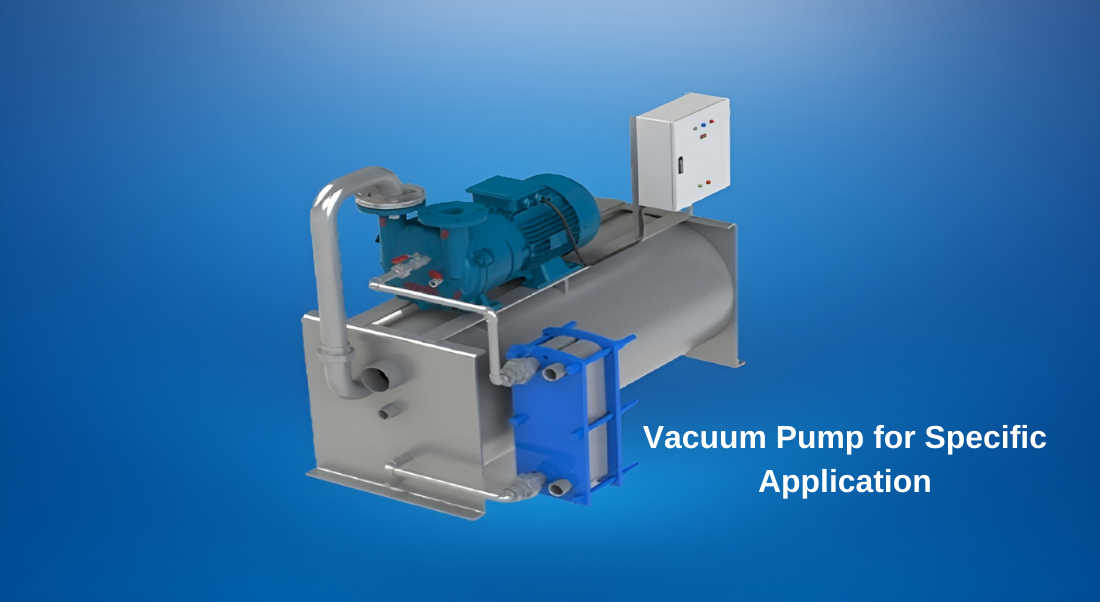

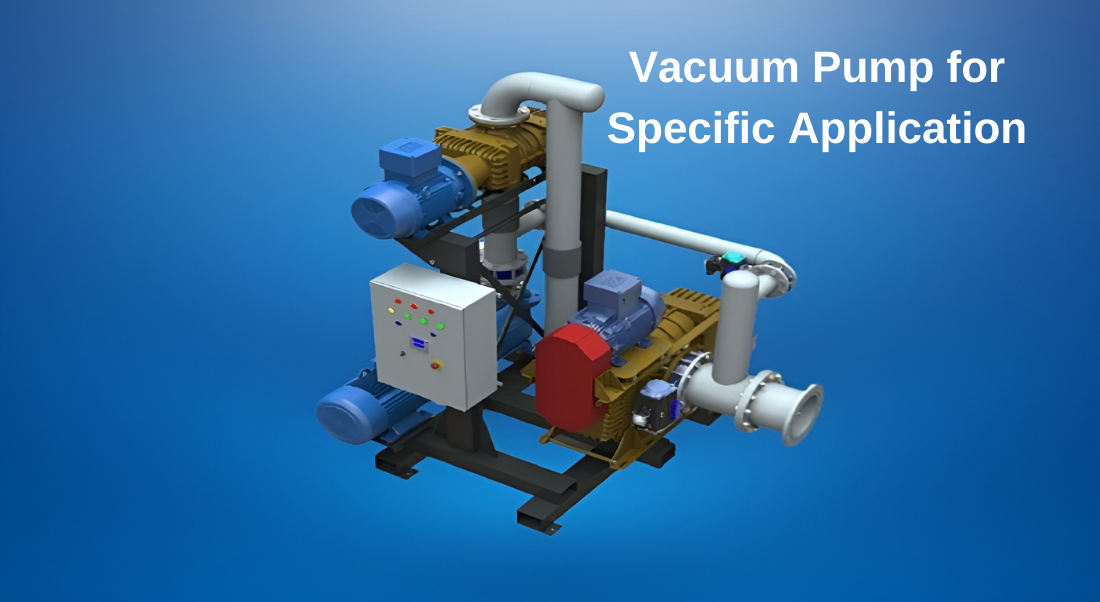

Vacuum Pump for Specific Application

Contents

- What is a Vacuum Pump?

- Which Vacuum Pump is Most Suitable for Specific Applications?

- How to Improve the Performance of a Vacuum Pump?

- What are the Different Types of Vacuum Pumps?

- How Should Vacuum Pump Maintenance Be Done?

- How to Ensure Energy Efficiency of a Vacuum Pump?

- How to Install a Vacuum Pump for Specific Applications?

What is a Vacuum Pump?

A vacuum pump is a mechanical device used to reduce the pressure inside a chamber or container. Essentially, it lowers the pressure within a closed system by creating a vacuum. This allows it to pull gases or liquids outwards or push external substances inwards.

Vacuum pumps are widely used in many industrial, commercial, and scientific applications. For example, vacuum pumps are used in the chemical industry for controlling reactions, vacuum packaging processes, manufacturing of medical devices, laboratory research, semiconductor production, aerospace, and space industry, among various other fields.

A vacuum pump can typically have different designs such as rotary vane, piston, or jet types. Each type offers specific advantages and disadvantages suitable for particular applications and requirements. For instance, rotary vane vacuum pumps are commonly used to meet industrial vacuum needs, while piston pumps may be preferred for achieving higher vacuum levels in laboratory and scientific applications.

The use of vacuum pumps can enhance the reliability and performance of systems, improve process efficiency, and enhance product quality. However, it is important to carefully select the right vacuum pump and perform proper maintenance; otherwise, functionality may decrease or malfunctions may occur. Therefore, it is important to carefully assess application requirements and select the appropriate pump.

Which Vacuum Pump is Most Suitable for Specific Applications?

Determining the most suitable vacuum pump for a specific application requires considering a range of factors. Each application varies in its characteristics, requirements, and operating conditions, thus the selection of the most suitable vacuum pump also varies accordingly.

Some factors to consider in determining the suitability of a vacuum pump for a specific application include:

Vacuum Level: The vacuum level required by the application determines which type of vacuum pump is suitable. Different pump types may be required for low, medium, or high vacuum levels.

Variability in Flow Rate: The flow rate requirements of the application determine how fast or slow the pump needs to operate. Different pump types may be preferred for applications requiring high flow rates.

Operating Environment: Factors such as temperature, pressure, and the presence of chemical substances in the environment where the pump will operate are important in pump selection. Pumps constructed with durable materials resistant to chemicals should be preferred.

Ease of Maintenance: Applications with low and continuous maintenance requirements are preferred. Therefore, maintenance requirements and costs should also be considered.

Cost: The budget of the application is an important factor in pump selection. The pump with the most suitable price-performance ratio should be selected.

Determining the most suitable vacuum pump involves analyzing the characteristics, requirements, and operating conditions of a specific application in detail. With this analysis, it will be easier to determine the most suitable vacuum pump for a specific application.

How to Improve the Performance of a Vacuum Pump?

Improving the performance of a vacuum pump is often achieved by making it operate more efficiently and achieving higher vacuum levels or flow rates through various methods. Here are some common methods to improve the performance of a vacuum pump:

Regular Maintenance: Regularly cleaning, lubricating, and maintaining the vacuum pump is important. Cleaning filters and regularly changing oil improves the efficiency of the pump.

Optimized Operating Conditions: Ensure that the pump operates at optimal temperature, pressure, and flow rates. The operating environment of the pump is one of the factors that affect its performance.

Reducing Air Leaks: Finding and sealing air leaks in the vacuum system can improve the pump's performance. Detecting and fixing leaks can help achieve higher vacuum levels.

Modifications to Increase Pump Efficiency: Upgrading or changing the mechanical or electrical components of the pump can improve its performance. For example, a more efficient motor or a more effective suction system can increase the pump's performance.

System Optimization: Optimizing the design and configuration of the vacuum system can improve the pump's performance. This may include arranging pipeline layouts, positioning valves correctly, and determining the correct vacuum chamber sizes.

Better Cooling: Improving the pump's cooling system can provide longer periods of higher performance. Improving the circulation of cooling water or using more effective cooling fans can prevent the pump from overheating.

These methods are some effective strategies that can be used to improve the performance of a vacuum pump. However, careful analysis should be done to determine the most suitable methods for each application.

What are the Different Types of Vacuum Pumps?

Vacuum pumps are essential equipment used in various industrial and commercial applications, and they come in a variety of different types. Here are some commonly used types of vacuum pumps:

Rotary Vane Pumps: Rotary vane pumps are mechanical pumps that create a vacuum by the rotation of vanes or blades. Due to their simple design and wide range of applications, they are commonly used.

Liquid Ring Pumps: Liquid ring pumps create a vacuum by forming a liquid ring through rotational movement. The liquid ring is continuously refreshed during operation, providing a seal.

Diaphragm Pumps: Diaphragm pumps are a type of pump that creates a vacuum using the movement of a diaphragm. These pumps can be used in applications where contaminated substances need to be pumped as they provide a seal.

Scroll Pumps: Scroll pumps are pumps that create a vacuum using spiral-shaped moving parts. They are preferred for their simple design and low maintenance requirements.

Turbo Pumps: Turbo pumps create a vacuum using high-speed rotating rotors and stators. They can reach high vacuum levels and are often used in applications requiring high precision.

Dry Screw Pumps: Dry screw pumps use one or more screws to create a vacuum. They operate on an oil-free principle and are preferred in various industrial applications.

These are just a few of the vacuum pump types, each with specific advantages and applications. The selection of the appropriate pump depends on the requirements of a particular application, operating environment, and other factors.

How Should Vacuum Pump Maintenance Be Done?

Regular maintenance of vacuum pumps is important for longevity and reliable performance. Here are the basic steps for vacuum pump maintenance:

Filter Cleaning and Replacement: Filters located at the air inlet of vacuum pumps prevent dust and dirt buildup. Filters may need to be cleaned or replaced at regular intervals.

Checking Oil Level: Oil-lubricated vacuum pumps should ensure that the oil level is maintained properly during operation. Low oil levels can cause the pump to overheat and decrease performance.

Oil Change: Oil-lubricated vacuum pumps require oil changes at regular intervals. This ensures the pump operates effectively and has a longer lifespan. Oil change intervals should be according to the manufacturer's instructions.

Cooling System Maintenance: Some vacuum pumps have cooling systems that require regular cleaning and maintenance to prevent overheating.

Checking and Replacing Seals: Seals in vacuum pumps are important for sealing and performance. Seals should be checked regularly and replaced when necessary.

General Checks: The overall condition of the pump and its components should be checked regularly. Leaks, damages, or wear may require troubleshooting or replacement of parts.

These maintenance steps improve the efficiency of the vacuum pump while ensuring its safety and longevity. Each vacuum pump model and manufacturer may have specific maintenance requirements, so it is important to follow maintenance instructions and manufacturer recommendations.

How to Ensure Energy Efficiency of a Vacuum Pump?

Several strategies can be employed to increase the energy efficiency of vacuum pumps:

Proper Pump Selection: Choose the vacuum pump that best suits the application's needs. Smaller capacity

pumps may be more efficient for applications with lower demand. Additionally, consider the vacuum level and flow rate requirements.

Prefer High-Efficiency Models: Opt for vacuum pumps with advanced technology that consume less energy and offer lower operating costs. Therefore, researching the best options in terms of energy efficiency is important.

Use Frequency Controlled Drives: Utilizing frequency-controlled drives to control the pump's speed can increase energy efficiency. This allows the pump to operate at lower speeds, consuming less energy as needed.

Optimize Operating Parameters: The operating parameters of vacuum pumps significantly affect energy efficiency. Parameters such as pump speed, vacuum level, and flow rate should be adjusted to optimal levels.

Regular Maintenance: Regular maintenance of vacuum pumps is crucial for maintaining energy efficiency. Clean filters, proper lubrication, and other maintenance tasks ensure the pump operates efficiently.

Monitoring and Analysis: Monitoring the operating efficiency of vacuum pumps and analyzing energy consumption can help identify areas for improvement. Making necessary adjustments based on this analysis can reduce unnecessary energy consumption.

Energy efficiency not only reduces operating costs but also minimizes environmental impact. Therefore, investments made to improve the energy efficiency of vacuum pumps are often profitable in the long run.

How to Install a Vacuum Pump for Specific Applications?

Proper installation of a vacuum pump for a specific application is crucial to ensure optimal performance and reliability. Here are the steps for installing a vacuum pump for a specific application:

Identify Application Requirements: The first step is to determine the vacuum pump requirements for a specific application. This includes factors such as vacuum level, flow rate, operating environment, and other technical specifications.

Select the Right Pump: Choose a vacuum pump that meets the requirements of the application. Consider factors such as vacuum level, flow capacity, operating pressure, and chemical resistance when selecting the pump.

Choose the Installation Location: The vacuum pump should be installed in a suitable location. It should be well-ventilated and positioned to accommodate the operating environment.

Pump Connections: Properly mount the pump and connect it to the vacuum line and suction line. Connections should be leak-proof and properly tightened.

Power Connection: The vacuum pump should be connected to the appropriate power source. Electrical connections should be made in accordance with safety standards, and necessary protective devices should be used.

Testing and Adjustments: After pump installation, the system should be tested, and necessary adjustments should be made. Vacuum level, flow rate, and other parameters should be checked and adjusted as needed.

Compliance with Maintenance Instructions: The vacuum pump should be maintained according to the manufacturer's instructions and recommendations. Regular maintenance ensures the pump operates reliably and efficiently.

Safety Precautions: Safety precautions should be observed during pump installation. Proper installation and operation of the pump contribute to occupational safety.

These steps ensure that the vacuum pump is installed correctly for a specific application, resulting in optimal performance and reliability.