Vacuum Pump in Automotive Industry

Table of Contents

- What Functions Do Vacuum Pumps Perform in the Automotive Industry?

- What Is the Importance of Vacuum Pumps in Automotive Systems?

- What Should Be Considered When Choosing Vacuum Pumps in Automotive Applications?

- Where Are Vacuum Pumps Used in Automotive Parts?

- How Is Maintenance of Vacuum Pumps Done in the Automotive Industry?

- What Does the Performance of Vacuum Pumps in Automotive Systems Depend On?

- What Are the Advantages of Vacuum Pumps for Automotive Manufacturers?

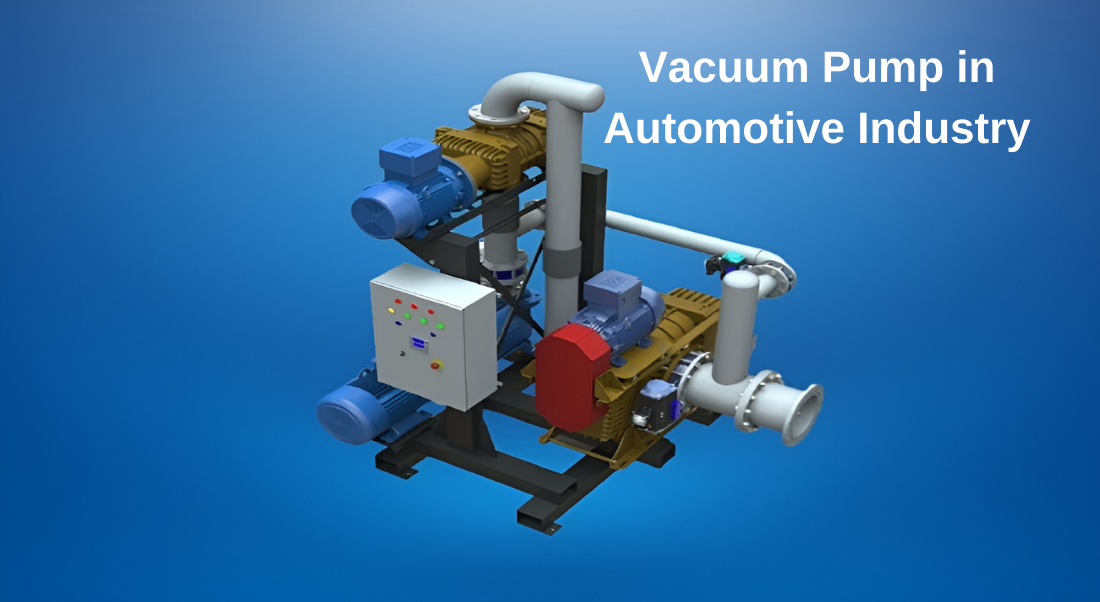

What Functions Do Vacuum Pumps Perform in the Automotive Industry?

Vacuum pumps in the automotive industry serve various important functions and ensure the proper functioning of automotive systems. These pumps assist in creating vacuum in engines, supporting the operation of systems such as brake systems, emission control systems, and locked differentials. Particularly, vacuum pumps enhance braking power by creating vacuum pressure in hydraulic brake systems, ensuring safer driving experiences. Additionally, vacuum pumps used in emission control systems aid in cleaning exhaust gases and reducing emissions, thereby minimizing the environmental impact of vehicles and providing a more eco-friendly driving experience. Vacuum pumps also provide vacuum power in systems like locked differentials, improving traction and control of the vehicle under challenging road conditions. In conclusion, vacuum pumps in the automotive industry perform crucial functions to enhance safety, reduce emissions, and optimize performance.

What Is the Importance of Vacuum Pumps in Automotive Systems?

Vacuum pumps play a critical role in automotive systems. These pumps are used to support the operation of various automotive components and perform many important functions. Primarily, many braking systems, such as hydraulic brake systems, operate with vacuum pumps. These pumps enhance braking power by creating hydraulic pressure, reducing the stopping distance of the vehicle and ensuring safer driving. Additionally, vacuum pumps are used in emission control systems. By cleaning exhaust gases and reducing emissions, they minimize the vehicle's environmental impact. Furthermore, vacuum pumps provide vacuum power in systems like locked differentials, improving the vehicle's traction and grip under challenging road conditions. In conclusion, vacuum pumps are of critical importance in the automotive industry in terms of safety, environmental impact, and performance.

What Should Be Considered When Choosing a Vacuum Pump in Automotive Applications?

There are several important factors to consider when choosing a vacuum pump in automotive applications. Firstly, reliability and durability of the pump are crucial. Vacuum pumps used in automotive systems should be long-lasting and consistently provide high performance. Additionally, compatibility of the pump should be taken into account. The selected vacuum pump should have features compatible with the model and systems of the vehicle. Furthermore, ease of maintenance of the pump should also be considered. Being easily accessible and cleanable can reduce operating costs in the long run. Moreover, efficiency and energy consumption of the pump are also important. A more efficient vacuum pump can lead to fuel savings and reduce environmental impact. Finally, the reliability of the pump manufacturer and the warranty services provided should also be taken into consideration. All these factors should be considered when selecting a vacuum pump in automotive applications, and the right choice can provide long-term performance and reliability.

Which Automotive Parts Use Vacuum Pumps?

Vacuum pumps are used in various important parts in the automotive industry, ensuring proper functioning of the vehicle. Especially, hydraulic brake systems operate with vacuum pumps. These pumps enhance braking power by creating brake fluid, shortening the stopping distance of the vehicle, and ensuring safe driving. Additionally, vacuum pumps are used in turbocharger systems. In turbocharged engines, vacuum pumps enable more effective operation of the turbocharger, enhancing engine performance. Exhaust gas recirculation (EGR) systems also operate with vacuum pumps. These systems reduce emissions by recirculating exhaust gases back into the intake manifold. Moreover, vacuum pumps are used in systems like the locked differential. These pumps lock the differential, providing better traction and grip in challenging road conditions. By being used in many crucial parts of the automotive industry, vacuum pumps help optimize the performance, safety, and environmental impact of vehicles.

How Is Maintenance of Vacuum Pumps Done in the Automotive Industry?

Regular maintenance of vacuum pumps in the automotive industry is vital for vehicle safety and performance. Maintenance of vacuum pumps ensures their longevity and smooth operation. The first step in maintenance is cleaning the pump. Dust, dirt, or other residues can negatively affect the performance of the pump, so it is important to periodically clean the exterior of the pump. Additionally, it is important to check the tightness of the connections of the vacuum pump and tighten them if necessary. Furthermore, the oil level of the vacuum pump should be regularly checked. Low oil levels can cause the pump to overheat and damage. If the oil level is low, appropriate oil should be added. Inspection of the internal mechanism of the vacuum pump is also necessary during maintenance. Parts may need to be replaced or renewed if necessary. However, maintenance of vacuum pumps can be a complex task, so consulting with a specialist mechanic or service center may be safer. All these steps ensure the longevity of the vacuum pump and maintain the safety and performance of the vehicle.

What Factors Determine the Performance of Vacuum Pumps in Automotive Systems?

The performance of vacuum pumps in automotive systems depends on several important factors, and managing these factors correctly is critical for the efficiency and safety of the vehicle. Firstly, the quality of the vacuum pump has a significant impact on performance. A vacuum pump manufactured from high-quality and durable materials provides more stable and reliable performance. Additionally, proper installation and connection of the vacuum pump are important. Correct assembly ensures the efficient operation of the pump and compatibility with other components of the system. Furthermore, regular maintenance and cleaning of the vacuum pump are also determining factors for performance. A clean vacuum pump can create a more effective vacuum and prevent potential issues in the system. Lastly, the overall mechanical condition of the vehicle and its compatibility with other components also affect the performance of the vacuum pump. Careful management of all these factors ensures the reliable and effective operation of vacuum pumps in automotive systems.

What Are the Advantages of Vacuum Pumps for Automotive Manufacturers?

Vacuum pumps offer a range of advantages for automotive manufacturers, positively impacting the performance, safety, and environmental impact of vehicles. Firstly, vacuum pumps ensure the reliable operation of critical systems such as hydraulic brake systems, enhancing the safety of drivers for a more secure driving experience. Additionally, vacuum pumps are indispensable for emission control systems, cleaning exhaust gases and reducing emissions to minimize the environmental impact of vehicles. Moreover, vacuum pumps are crucial for turbocharger systems, enhancing engine performance by enabling more efficient operation of turbochargers in turbocharged engines. Vacuum pumps are also used in systems like locked differentials, providing better traction and grip for vehicles in challenging road conditions. Overall, vacuum pumps offer significant advantages for automotive manufacturers, including increased safety, reduced emissions, optimized performance, and minimized environmental impact, making them an essential component in the automotive industry.