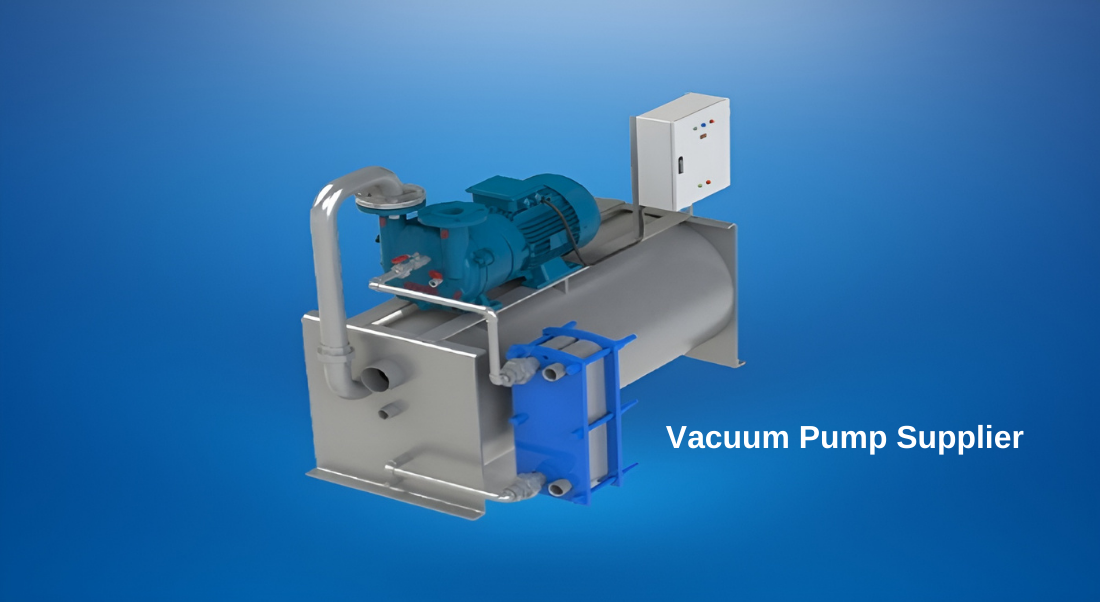

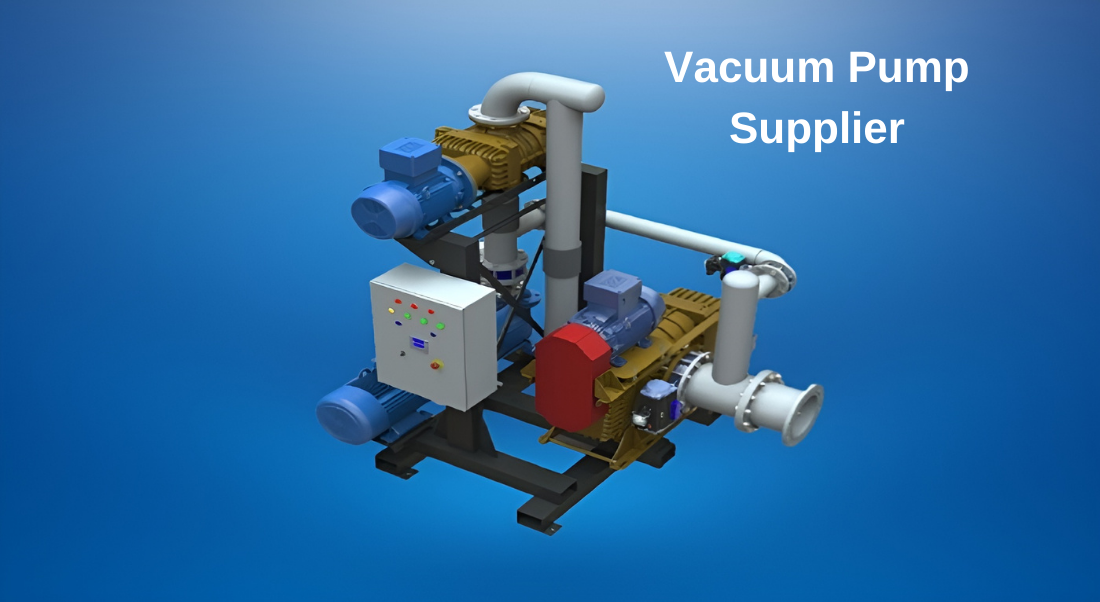

Vacuum Pump Supplier

Contents

- What Types of Vacuum Pumps Do You Offer?

- What Industries Do You Typically Supply Vacuum Pumps To?

- Can You Provide Custom Solutions for Specific Applications?

- What Is the Typical Lead Time for Ordering and Receiving Vacuum Pumps?

- Do You Offer Warranty or Support Services for Your Vacuum Pumps?

- Are Your Vacuum Pumps Energy-Efficient?

What Types of Vacuum Pumps Do You Offer?

As a leading vacuum pump supplier, we offer a comprehensive range of vacuum pumps designed to meet various industrial, commercial, and scientific needs. Our product line includes several types of vacuum pumps, each tailored to specific applications and performance requirements.

One of the primary types of vacuum pumps we offer is the rotary vane pump. Rotary vane pumps are widely used for their robustness, reliability, and versatility. They operate by using rotating vanes to create a vacuum, making them suitable for applications such as vacuum packaging, HVAC systems, and laboratory processes.

In addition to rotary vane pumps, we also provide liquid ring pumps, which utilize a rotating liquid ring to generate vacuum pressure. These pumps are well-suited for applications involving wet or humid gases, such as in the chemical processing industry.

For applications requiring oil-free operation and minimal maintenance, our range includes diaphragm pumps. These pumps feature a flexible diaphragm that moves back and forth to create suction, making them ideal for sensitive processes in industries such as pharmaceuticals and food processing.

Furthermore, our catalog includes scroll pumps, which use spiral-shaped scrolls to compress gas and create vacuum. Scroll pumps are known for their quiet operation, high efficiency, and low vibration, making them suitable for laboratory and scientific applications.

For ultra-high vacuum requirements, we offer turbo pumps, which utilize high-speed rotating blades to achieve extremely low pressures. These pumps are commonly used in semiconductor manufacturing, particle accelerators, and research laboratories.

Lastly, our lineup includes dry screw pumps, which provide oil-free vacuum generation and are ideal for applications where contamination must be minimized, such as in the semiconductor and electronics industries.

Overall, our range of vacuum pumps encompasses a variety of technologies to cater to diverse applications, ensuring that our customers find the perfect solution for their specific vacuum needs.

What Industries Do You Typically Supply Vacuum Pumps To?

Certainly! We typically supply vacuum pumps to a wide range of industries that rely on vacuum technology for various processes and applications. Some of the industries we commonly serve include:

Chemical Processing: In the chemical processing industry, vacuum pumps are used for tasks such as distillation, filtration, drying, and degassing. They play a crucial role in creating vacuum conditions necessary for these processes to occur efficiently and effectively.

Pharmaceutical and Biotechnology: Vacuum pumps are essential in pharmaceutical and biotechnology industries for tasks like solvent recovery, freeze drying, and molecular distillation. They ensure the integrity and purity of pharmaceutical products and facilitate the production of vaccines, medicines, and biopharmaceuticals.

Food and Beverage: Vacuum pumps are used in the food and beverage industry for packaging applications such as vacuum sealing, vacuum packaging, and vacuum cooling. They help extend the shelf life of food products, preserve freshness, and maintain product quality.

Manufacturing and Production: Vacuum pumps play a vital role in various manufacturing processes, including vacuum metallurgy, composite manufacturing, and electronics production. They are used for degassing, impregnation, and vacuum molding operations, among others.

Automotive: In the automotive industry, vacuum pumps are utilized for applications such as brake system operation, engine crankcase ventilation, and emissions control. They ensure proper functioning of automotive systems and contribute to vehicle safety and performance.

Aerospace and Defense: Vacuum pumps are integral to aerospace and defense applications such as space simulation chambers, satellite propulsion systems, and vacuum heat treatment. They enable the testing, manufacturing, and maintenance of aerospace components and systems.

Research and Development: Vacuum pumps are extensively used in research laboratories, universities, and R&D facilities for experiments, analytical instrumentation, and scientific studies. They support a wide range of research areas, including physics, chemistry, biology, and material science.

Environmental and Energy: Vacuum pumps play a role in environmental monitoring, pollution control, and renewable energy production processes. They are used in applications such as wastewater treatment, air sampling, and solar panel manufacturing.

Medical and Healthcare: Vacuum pumps are essential in medical and healthcare settings for applications like medical gas delivery, vacuum-assisted wound closure, and laboratory equipment operation. They contribute to patient care, diagnostic procedures, and medical research.

Packaging and Printing: Vacuum pumps are utilized in packaging and printing industries for tasks such as vacuum forming, vacuum packaging, and paper handling. They enable precise control and manipulation of materials during the packaging and printing processes.

In summary, our vacuum pumps find widespread use across various industries, supporting critical processes, enhancing efficiency, and ensuring the quality and safety of products and applications.

Can You Provide Custom Solutions for Specific Applications?

Certainly! We specialize in providing custom solutions tailored to meet the specific needs and requirements of our clients' applications. Our team of experts works closely with customers to understand their unique challenges, objectives, and technical specifications. Here's how we approach providing custom solutions:

Consultation and Assessment: We begin by conducting thorough consultations with our clients to gain insights into their specific application requirements. This involves understanding the operational environment, performance criteria, space constraints, and any other relevant factors.

Engineering and Design: Our experienced engineering team utilizes state-of-the-art design tools and technologies to develop customized solutions that address the identified needs. Whether it involves modifying existing products or designing entirely new systems, we ensure that the solution is optimized for performance, reliability, and efficiency.

Prototyping and Testing: We then proceed to create prototypes of the custom solution, which undergo rigorous testing and validation processes. This allows us to verify the functionality, durability, and performance of the solution under real-world conditions, ensuring that it meets the specified requirements.

Collaborative Iteration: Throughout the development process, we maintain open communication channels with our clients, soliciting feedback and incorporating any necessary revisions or adjustments. This collaborative approach ensures that the final solution aligns perfectly with the client's expectations and objectives.

Manufacturing and Deployment: Once the custom solution has been finalized and approved, we move forward with the manufacturing process. Our advanced manufacturing facilities and quality assurance protocols ensure that the solution is produced to the highest standards of precision and reliability. We also provide comprehensive support during the deployment and integration phases to ensure seamless implementation.

Continuous Support and Optimization: Our commitment to customer satisfaction extends beyond the initial deployment. We offer ongoing support, maintenance, and optimization services to ensure that the custom solution continues to perform at peak levels over its entire lifecycle. This includes proactive monitoring, troubleshooting, and periodic upgrades as needed.

Whether it's designing specialized vacuum systems for unique industrial processes, developing custom pump configurations for specific applications, or engineering tailored solutions to meet complex technical challenges, we have the expertise and capabilities to deliver innovative custom solutions that exceed expectations.

What Is the Typical Lead Time for Ordering and Receiving Vacuum Pumps?

The typical lead time for ordering and receiving vacuum pumps can vary depending on several factors, including the type of pump, its specifications, and the supplier's production and shipping processes. Generally, lead times can range from a few days to several weeks or even months, especially for custom or specialized orders. Here's an overview of the factors that can influence lead times:

Stock Availability: If the vacuum pump is readily available in the supplier's inventory, the lead time may be relatively short, typically ranging from a few days to a week. However, if the pump needs to be manufactured or sourced from a third-party supplier, the lead time may be longer.

Customization Requirements: For custom or specialized vacuum pumps tailored to specific applications, the lead time is often longer due to the engineering, design, and manufacturing processes involved. Customization may include modifications to pump specifications, materials, configurations, or other parameters to meet the customer's unique requirements.

Production Capacity: The supplier's production capacity and workload can also impact lead times. If the supplier is experiencing high demand or production constraints, lead times may be extended. Conversely, suppliers with ample production capacity and efficient workflows may offer shorter lead times.

Shipping and Logistics: Lead times are also influenced by shipping and logistics factors, such as transportation mode, distance, customs clearance, and delivery schedules. International orders may have longer lead times due to additional transit and customs processing times.

Order Volume: Larger order volumes or bulk purchases may require additional time for processing, manufacturing, and fulfillment compared to smaller orders. Suppliers may offer expedited services for urgent orders, but this often comes at an extra cost.

Communication and Coordination: Effective communication and coordination between the supplier and the customer can help streamline the ordering process and minimize lead times. Clear communication regarding order specifications, delivery expectations, and any potential delays is essential for managing expectations and ensuring timely delivery.

Overall, it's important for customers to plan ahead and consider potential lead times when ordering vacuum pumps to avoid any delays in their projects or operations. Working closely with a reliable supplier and providing detailed requirements can help expedite the ordering and delivery process.

Do You Offer Warranty or Support Services for Your Vacuum Pumps?

we offer comprehensive warranty and support services for all our vacuum pumps to ensure customer satisfaction and peace of mind. Our warranty coverage typically includes protection against defects in materials and workmanship for a specified period from the date of purchase.

Under our warranty program, customers are entitled to repair or replacement of any defective parts or components, free of charge, during the warranty period. This warranty coverage demonstrates our commitment to delivering high-quality products and standing behind their performance and reliability.

In addition to warranty coverage, we provide ongoing support services to assist customers with any inquiries, technical issues, or maintenance needs related to their vacuum pumps. Our knowledgeable support team is readily available to offer guidance, troubleshooting assistance, and recommendations to optimize the performance and longevity of the pumps.

Our support services may include remote assistance, onsite visits for troubleshooting or maintenance, access to technical documentation and resources, and training programs for customers and their staff. We strive to ensure that our customers have the necessary support and resources to maximize the efficiency, reliability, and lifespan of their vacuum pumps.

By offering warranty and support services, we aim to build long-term partnerships with our customers based on trust, reliability, and exceptional service. Our goal is to exceed customer expectations and provide a seamless experience throughout the entire lifecycle of our vacuum pumps, from purchase to operation and maintenance.

Are Your Vacuum Pumps Energy-Efficient?

our vacuum pumps are designed with energy efficiency in mind to minimize energy consumption and operating costs while maximizing performance. We prioritize the development and implementation of innovative technologies and engineering solutions aimed at enhancing energy efficiency across our product range.

One of the key strategies we employ to achieve energy efficiency is the utilization of advanced motor designs and control systems. Our vacuum pumps are equipped with high-efficiency motors that are optimized for energy savings without compromising on performance. Additionally, we integrate intelligent control systems that dynamically adjust pump operation based on demand, allowing for energy consumption to be optimized in real-time.

Furthermore, we focus on improving the overall design and construction of our vacuum pumps to minimize energy losses and maximize operational efficiency. This includes the use of high-quality materials, precision engineering, and aerodynamic optimization to reduce friction, heat generation, and other inefficiencies.

In addition to the design aspect, we offer energy-efficient solutions through the implementation of ancillary technologies such as variable frequency drives (VFDs) and regenerative braking systems. These technologies enable better control over pump speed and power consumption, allowing for further energy savings during operation.

Moreover, we provide comprehensive energy efficiency evaluations and consulting services to help customers optimize the performance of their vacuum systems. Our experts assess the specific requirements and operating conditions of each application to identify opportunities for energy savings and recommend tailored solutions accordingly.

Overall, our commitment to energy efficiency extends throughout the entire lifecycle of our vacuum pumps, from design and manufacturing to operation and maintenance. By offering energy-efficient solutions, we help our customers reduce their environmental footprint, lower operating costs, and achieve sustainable performance goals.