What is Monoblock Vacuum Pump? What are the Usage Areas?

What is Monoblock Vacuum Pump and How Does It Work?

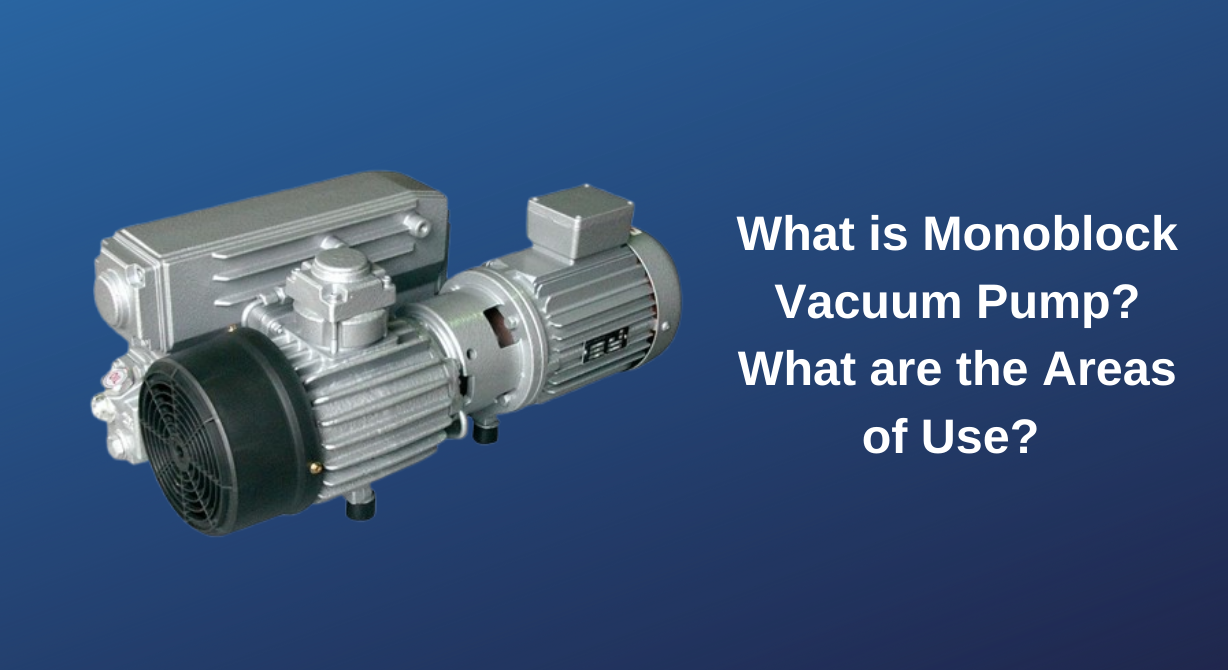

Monoblock Vacuum Pump is a specialised vacuum creating device used in industrial and commercial applications. These pumps are usually compactly designed in a single block, which makes installation easier and saves space. The basic function of the Monoblock Vacuum Pump is to suck air or gas from a closed system, creating a vacuum in that system.

The working principle is realised by the rotation of a rotor inside the pump. The rotor has vanes that are used to suck in air or gas. The rotational movement allows the sucked substance to be transported to a cavity inside the pump, which creates the vacuum. This process creates a low pressure environment and at the outlet of the vacuum pump can deliver this low pressure environment to the user or application.

The advantages of the Monoblock Vacuum Pump include compact design, low maintenance and energy efficiency. It also offers a wide range of uses in industrial processes. These pumps often provide an ideal solution for vacuum packaging, automotive, printing, electronics manufacturing and many other industrial applications.

What Kind Of Applications Is a Monoblock Vacuum Pump Used In?

Monoblock Vacuum Pump is a special vacuum technology that offers a wide range of applications in industrial processes. With its compact design and powerful performance, these pumps provide significant advantages in many sectors. At the heart of industrial automation, the Monoblock Vacuum Pump offers a reliable solution for material handling, placing and processing applications in production lines.

In the packaging industry, the Monoblock Vacuum Pump is frequently used in vacuum packaging systems. In the packaging of food, pharmaceutical and other industrial products, this pump increases the sealing of the packaging, extending the shelf life of the products and keeping them fresh.

In the printing industry, the Monoblock Vacuum Pump plays a critical role in the processing of paper or other materials. In precision printing processes, the attachment and processing of materials to a fixed table makes it possible to achieve high quality results thanks to the superior performance of these pumps.

In electronics manufacturing, the Monoblock Vacuum Pump is used for the safe handling and assembly of sensitive components. This improves product quality by enabling fast and reliable manipulation in production processes in the electronics industry.

With its compact design and wide range of applications, the Monoblock Vacuum Pump offers a leading solution for industrial applications, increasing productivity and optimising work processes.

What Are The Advantages of Monoblock Vacuum Pump?

Monoblock Vacuum Pump offers a number of advantages as a vacuum technology used in industrial applications. These vacuum pumps, which stand out with their compact design and effective performance, are preferred in many sectors.

One of the most important advantages of these pumps is their compact structure. The monoblock design integrates the pump in a single block, facilitating installation and saving space in the workplace. This helps users speed up their installation process and increase their productivity.

The Monoblock Vacuum Pump is also characterised by low maintenance requirements. Their robust and durable construction offers long life expectancy and keeps operating costs low. This increases the long-term investment value of users.

Energy efficiency is another advantage of the Monoblock Vacuum Pump. Thanks to its advanced design, it optimises energy consumption and offers an environmentally friendly solution. This feature provides an important advantage for businesses with sustainability goals.

What are the Technical Specifications of Monoblock Vacuum Pump?

Monoblock Vacuum Pump offers a special vacuum technology that provides reliable performance in industrial applications. The technical features of these vacuum pumps offer users a wide range of applications and an effective processing capacity.

Its powerful motor and specially designed rotor stand out with high suction power and fast vacuum generation capacity. This feature enables it to be used effectively in material handling and placement applications in industrial automation processes.

The compact design integrated in a single block makes these vacuum pumps user-friendly in terms of installation. The compact structure is an ideal solution for users working in limited spaces in industrial plants.

Technical features of the Monoblock Vacuum Pump include the ability to provide a wide range of air flow rates, low noise levels, high durability and low maintenance requirements. This ensures that users have a long-lasting and reliable vacuum solution.

Furthermore, the versatile connection options and control features that can adapt to various application requirements make the use of the Monoblock Vacuum Pump more flexible and customisable.

How to Ensure Energy Efficiency of Monoblock Vacuum Pump?

Monoblock Vacuum Pump offers an environmentally friendly vacuum solution in industrial applications by offering a high level of performance in energy efficiency. The energy efficiency of these pumps is ensured by various design features and technological innovations.

The special design optimises power consumption. Advanced rotor technology and intelligent control systems aim to achieve maximum performance by using energy efficiently. In this way, businesses can reduce energy costs and reduce environmental impact.

Low energy consumption enables the Monoblock Vacuum Pump to comply with sustainability targets. This feature allows businesses to save energy and minimise their environmental impact. High efficiency motors and intelligent energy management systems support low energy consumption in continuous operations.

Another factor that increases the energy efficiency of the Monoblock Vacuum Pump is its low maintenance requirements. The low number of parts requiring maintenance helps to maintain energy efficiency, as regular maintenance operations can often result in energy losses.

How to Maintain and Clean the Monoblock Vacuum Pump?

Maintenance and cleaning of the Monoblock Vacuum Pump is critical to ensure long life and continuous high performance. Regular maintenance of these vacuum pumps reduces operating costs and increases reliability.

The rotor and vanes inside the pump can become contaminated over time, which can cause loss of performance. Therefore, it is important to clean the rotor and check the vanes at regular intervals.

Regular replacement of filters is also an important maintenance step. Filters ensure that the air or gas entering the pump is cleaned. Clean filters help the pump run efficiently and save energy.

It is also important to check oil levels regularly and add oil if necessary. The oil inside the pump ensures a long-lasting performance by reducing friction and protecting the internal mechanism.

Maintenance of the Monoblock Vacuum Pump helps users to increase productivity and reliability. Following the maintenance instructions recommended by the manufacturer allows the pump to maintain its optimum performance and to detect malfunctions in advance.

What is the Durability and Life Expectancy of Monoblock Vacuum Pump?

Specially designed to provide a durable performance. These vacuum pumps stand out with their strong construction and innovative design, offering durability beyond industry standards.

One of the factors determining its durability is the quality of the materials used. High-quality and durable materials ensure reliable operation of the pump in various industrial environments and increase its wear resistance.

Since these vacuum pumps are often used in heavy-duty industries, they have a robust construction. Their impact resistance and ability to adapt to various operating conditions enable the Monoblock Vacuum Pump to deliver a durable performance even in harsh industrial environments.

The life expectancy of the Monoblock Vacuum Pump may vary depending on regular maintenance and operating conditions. However, a long life is generally expected as long as the manufacturer's recommended maintenance instructions are followed. The rugged design and use of durable materials allow these pumps to offer a long-term investment value.

It stands out as a reliable choice among industrial users with its durability and long life expectancy exceeding industry standards.